What is Prototype Machining?

Prototype machining has been widely used on the different stages of product development, such as concept design, visual presentation on the exhibition, function checking, engineer verification, even the low-volume preproduction.

No matter what the destination is, prototype machining undoubtedly can shorten the product development cycle, and finally achieve the purpose of cost saving. There are four below different prototype machining ways that are popular in all kinds of industries, not only on the automotive, medical device, but also the aerospace and safety defense, etc.

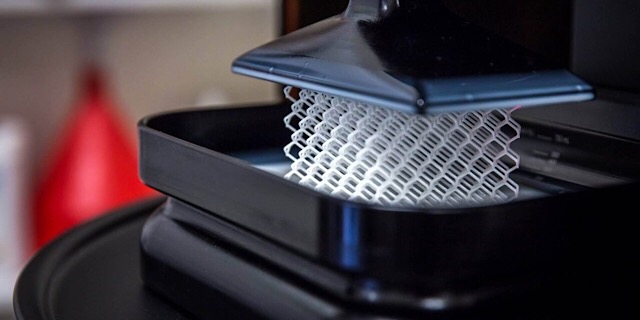

3D Printing

It is also called the “additive manufacture”. It can quickly prototype the products, especially when the structure design is complex and quantity is small. Besides, 3D printing can prototype special material, such as the elastomer, which is impossible for machining. However, the accuracy and strength of products are not the best.

3D printing has been widely used in the medical industry. For instance, it produces a variety of human organs and tissues including bones, ears, trachea, jaw bone, cells, glasses, blood vessels, tissues, as well as drugs and delivery devices. The largest advantage of 3D printing in medical industry is the cost and time effective which is good for low-volume prototypes and advance model validation.

CNC Machining

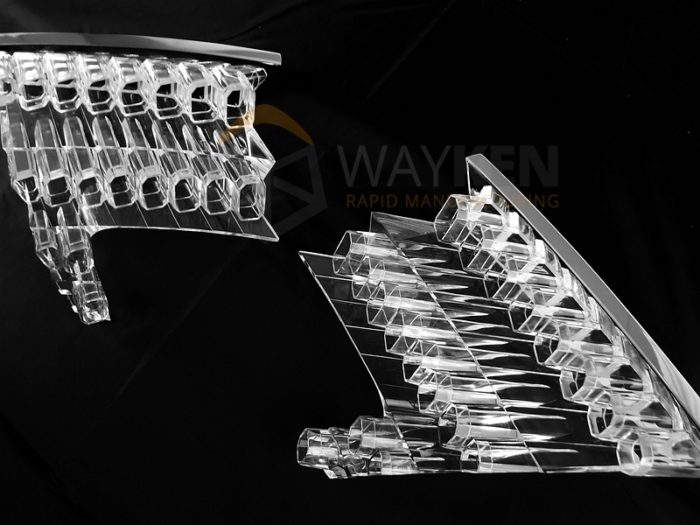

Currently, prototype CNC machining is the most common way, also called the “substraction manufacturing”. It can prototype products with higher accuracy and wide range of material selection, not only the metal, but also the plastic. Generally speaking, CNC machining services includes: milling, turning, EDM and wire EDM.

When we refer to the CNC milling, we have to talk about the continuous 5-axis CNC milling systems, which allow the movements of all five axes at the same time during machining. The biggest advantage is that it can machine complex design structure with a high accuracy, which can not be achieved by other technology. Besides, it doesn’t need the manual repositioning and then reduce the machining time. However, the cost is still higher than normal 3 axis CNC milling machining.

EDM and wire EDM, they can cover the shortage of CNC machining. For example, we all know that CNC machining will leave radius on the parts caused by the CNC tools, no matter how small the tool diameter is. But sometimes the radius is not allowed by customer, we will need the EDM process to eliminate it to achieve the right angle. Sometimes, when the parts have the deep and small hole, and the CNC tools can not machine, we will use the wire EDM to achieve.

As mentioned above, the 3D printing is widely used in the medical industry, but when it refers to the medical device, the prototype CNC machining will play an important role. Such as the hot topic, surgical robotics which is an advanced robotic platform designed to perform complex surgical procedures using minimally invasive methods, the every action for the robotics not only depends on the right command that system provide, but also the super highest accuracy for the whole machining parts.

Besides the robotics, prototype CNC machining is also important for auto industry, especially the high-end cars. Most of the parts for cars need to mechanical machine because the strength is important not only for the functional test or mass production. For example, the head light prototype, the optical property is critical which CNC machining Acrylic or PMMA material and then finish process of highly polish. If choosing the 3D printing , although the cost will be cheaper, but it can not have the perfect optical surface, normally the surface is vague and defective that can not be used for the functional test. But if the purpose is for checking the assembling, it is ok.

Urethane- Vacuum Casting

The biggest creature for vacuum casting process is that it can achieve the low volume prototype production quickly and cost effectively compared with CNC machining. It use Polyurethane as the material with a wide selection range, which property can similar to the engineering plastics. Besides, it can prototype similar rubber parts, which CNC machining can not achieve. The accuracy and finish surface is related to the master pattern, which can produce by CNC or 3D printing. For example, if we need the casting parts have the smooth surface, we could choose CNC machining and even polish the master pattern, and finally the casting parts can fully copy the characteristics of master pattern. When comes to the complex structure, we will choose the 3D printing to make the master pattern.

Besides, casting material can achieve the different colour effective by changing the composition ratios, but there is an unavoidable shortcomings, the engineer need do colour modulation and the colour degree is difficult to control among different batches of casting, which will cause the colour difference. So if the colour is necessary,, we could choose the painting after casting.

Normally, the life time for a silicon mold can produce 12-15 pieces casting parts, no more than 20 pieces. Because the soft characteristic of silicon mold, the continued using will cause the casting parts generate transformation and shrink, etc.

Rapid Inject molding

When the prototype parts quantity is large, and the vacuum casting is not cost and time effective, while it is used for the final confirmation before mass production for product development, the rapid inject molding undoubtedly the best choice, for which is one of the plastic molding. Normally, the aluminum mold and simple steel mold are selected for rapid inject molding in view of its lighter weight and easily machining to cost down.

Conclusion:

No one can directly tell which prototype machining type is the best, because they all have their own pros and cons. For designers, the most suitable for the design is the best because the wrong selection of machining way cannot demonstrate the original design and even waste time and money. Choosing the suitable prototype machining type and provide the best machining proposal to satisfy every designer, is the duty of prototype manufacture. We will evaluate every project carefully and support with pleasure.